In addition to our standard offerings, the CustomBulk division of RPP Containers has built specialized hopper containers in a wide range of sizes and shapes to fit targeted specifications. One such design highlighted today is for golf ball processing and storage. This project was an update to an old design still in use today that has been in circulation for more than ten years. Such longevity should speak to the quality of the container, the components used, and the precision of the construction.

Cómo almacenar y dispensar pelotas de golf: la solución en contenedores de tolva personalizados

The Challenge: How to store and dispense golf balls

RPP Containers stocks a selection of standard hopper bottom containers used in agriculture, manufacturing, and storage. These products are well-established in the market and have a proven reliability and quality track record. Hopper containers are partially collapsible bins with a base designed to allow material flow using a manual slide gate.

The Requirements

La capacidad de plegado permite un envío más eficiente entre proveedores y clientes cuando se devuelven contenedores vacíos, por no mencionar que se desperdicia menos espacio al guardar los contenedores durante la temporada baja. También hay que tener en cuenta que estos productos son totalmente reciclables una vez que llegan al final de su vida útil, de manera que ofrecen una solución ecológica para cualquier empresa que desee actualizar su proceso actual.

Our standard sizes of hopper containers come in 57” x 45” y 45” x 48” footprints. For the 57" x 45" specifically, different heights are available depending on the volume needed. You can expect longevity with any of our hopper containers since they are weather resistant and thus suitable for outdoor conditions.

La solución

Los resultados

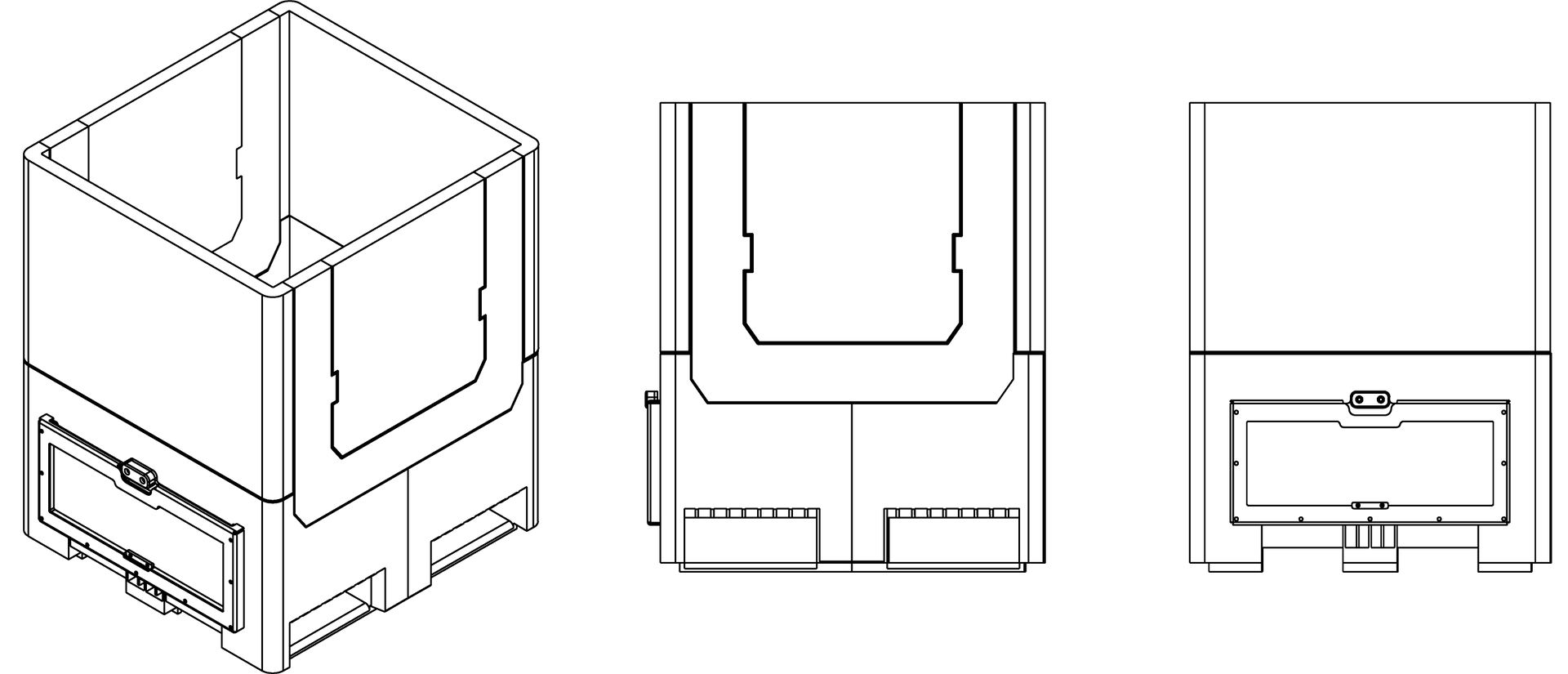

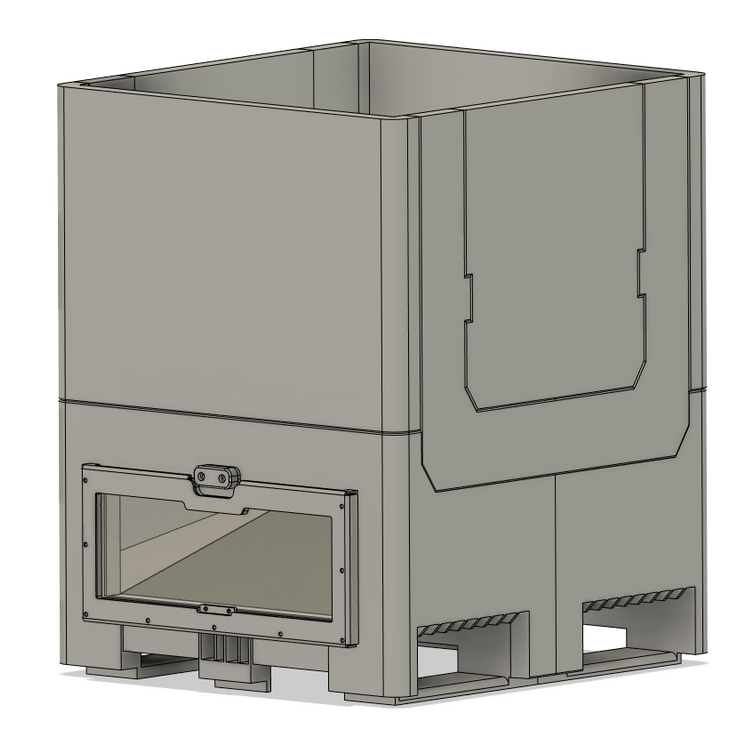

This design primarily focuses on using the small format 30" x 32" x 39" bulk container to emulate the function of a side-discharge hopper container. Being able to unload quickly but in a controlled manner was also a key feature.

Product flow is controlled by a manual slide gate gravity fed from a padded metal funnel insert set to an angle toward the opening. The padding is important since direct impact with the steel floor can damage golf balls easily. In addition to these characteristics, this container is collapsible to a height of just 13.8", making for a low profile when not in use.

The slide gate also serves as a viewing window allowing users to see inside without having to unstack or remove the cover. This gate is fully functional while containers are stacked. Underneath this container is a heavy-duty steel dolly which will grant mobility without needing a forklift or pallet jack. Up to two containers can be stacked on a single dolly, even when loaded with 1,500 lbs. each.

Custom containers like these can be used in various applications or modified for additional characteristics. The goal of any custom project is to help improve both safety and efficiency in operator workflow. This example allows products to move without heavy equipment such as a forklift or crane and is fully recyclable once it reaches the end of life.

¿Tiene preguntas?

Do you think a custom hopper bottom or another custom bulk container will be the solution to your application? Contact one of our knowledgeable account managers today. Call 1-800-945-8304 or Chat Live with one of our knowledgeable account managers Monday-Friday, 8 am-5 pm EST.

Enlaces para más información

Otras marcas

Copyright | RPP Containers.